Overview

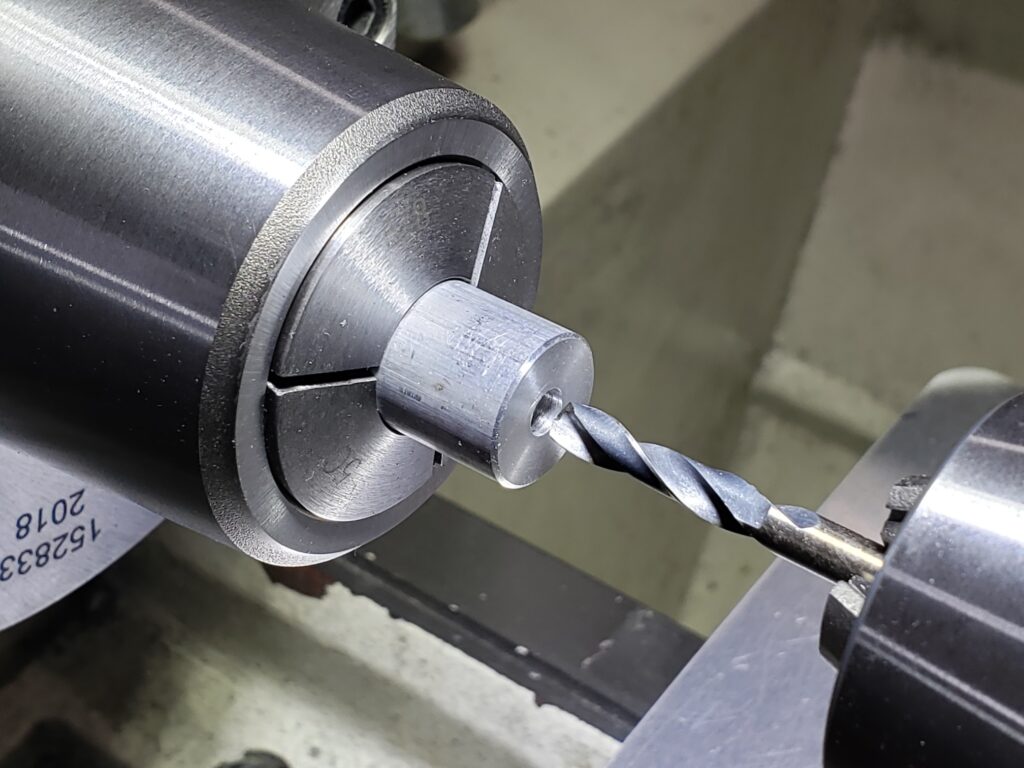

Carriage drilling is adding a drill chuck to the tool post and use it in lieu of the tail-stock.

I have never been real happy with using the tail-stock for drilling small holes (< 1/4″). This is mainly due to the mass and weight of the tail-stock which can easily overwhelm smaller drills. With the addition of the Solid-Block Compound Replacement mod some new capabilities are now possible:

- Precision alignment and recall of cutting tool offsets.

- More precise drilling and reaming of holes in the work-piece.

- Small holes are now easier to drill and ream.

- The carriage power feed may be used for a precise feed rate.

- Precise hole depth control using the DRO and/or the Electronic Leadscrew Stop Switch is now easier to achieve.

Requirements

While the following requirements may not be absolutely required they are highly recommended.

- A DRO is essential to use this function.

- The Solid-Block Compound Replacement mod is HIGHLY recommended. Else, you will be constantly fiddling with the compound to keep the spindle-drill chuck alignment true.

Considerations

The following items are shown as a starting point for implementing carriage drilling.

- Of paramount importance is to indicate the drill chuck center-line to the spindle center-line both fore, aft and vertically. The more precisely this is done the more accurate your setup will be.

- Large drills (> 1/2″) are not recommended due to carriage and cross-slide rigidity.

- Spot drills should be used in lieu of center drills for better accuracy.

- Short drills (machine screw/stubby drills) work best for accuracy due to drill flexing of longer drills.

Final Thoughts

I’m very pleased with the carriage drilling mod. Small holes are now a real pleasure to drill, ream and tap without the worry of breaking a tool.

(Click image to enlarge. Hit the browser back button to return)